Business management – Improve Business Strategy and Plant Manufacturing operations to meet Organizational Growth Plan

To enhance business strategy and manufacturing operations to align with organizational growth plans, several key strategies can be implemented:

- Market Analysis and Segmentation: Conduct a comprehensive market analysis to identify emerging trends, customer preferences, and competitive dynamics. Segment the market to target specific customer segments with tailored products and services.

- Product Portfolio Optimization: Evaluate the existing product portfolio and identify opportunities for innovation, differentiation, and expansion. Invest in research and development to develop new products or improve existing ones to meet evolving customer needs.

- Supply Chain Optimization: Strengthen the supply chain by enhancing supplier relationships, streamlining procurement processes, and implementing advanced inventory management systems. Embrace digital technologies like blockchain and IoT for real-time tracking and traceability.

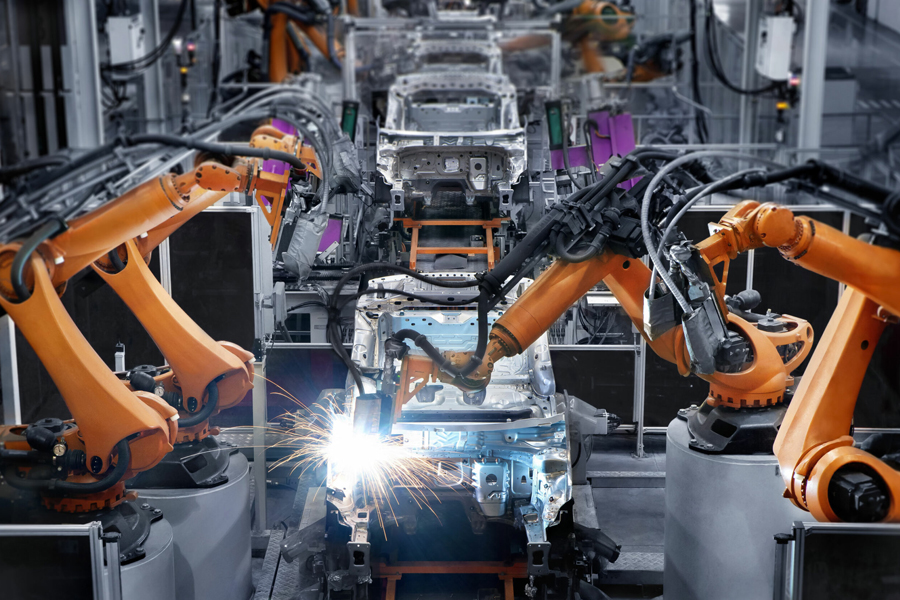

- Operational Efficiency: Implement lean manufacturing principles to optimize production processes, minimize waste, and reduce lead times. Invest in automation and robotics to improve productivity and flexibility while reducing labor costs.

- Quality Management: Prioritize quality throughout the manufacturing process by implementing robust quality control measures, conducting regular inspections, and fostering a culture of continuous improvement. Aim for zero-defect manufacturing to enhance customer satisfaction and brand reputation.

- Capacity Planning and Expansion: Anticipate future demand and invest in capacity expansion to accommodate growth projections. Conduct thorough feasibility studies for greenfield or brownfield projects to ensure optimal utilization of resources and mitigate risks.

- Talent Development and Retention: Invest in employee training and development programs to enhance skills and knowledge. Implement performance management systems to recognize and reward high performers, fostering employee engagement and retention.

- Technology Integration: Embrace digitalization and Industry 4.0 technologies to improve operational visibility, agility, and decision-making. Implement advanced analytics, AI, and machine learning algorithms to optimize production planning, scheduling, and maintenance.

- Sustainability and Corporate Responsibility: Integrate sustainability practices into manufacturing operations to minimize environmental impact and enhance brand reputation. Embrace renewable energy, waste reduction initiatives, and ethical sourcing practices to align with societal expectations.

- Strategic Partnerships and Alliances: Collaborate with strategic partners, suppliers, and industry associations to leverage complementary strengths, access new markets, and drive innovation. Foster long-term relationships based on mutual trust and shared objectives.